We want to define the various printing ink technologies and how they affect your signage projects. Ink technology has changed extensively over the past 20 years for large format inkjet printers and the sign industry. We’re deliberately omitting discussion of digital printers, those that are laser class or use heat thermo technologies.

Back in the day, signs were either painted using pounce patterns and enamel paints, or using an aqueous ink printer that created poster prints when could then be adhered to sign faces like wallpaper, using a paste roll-on glue.

Modern signs are now created with either direct print to substrates or vinyl prints with UV over-laminates.

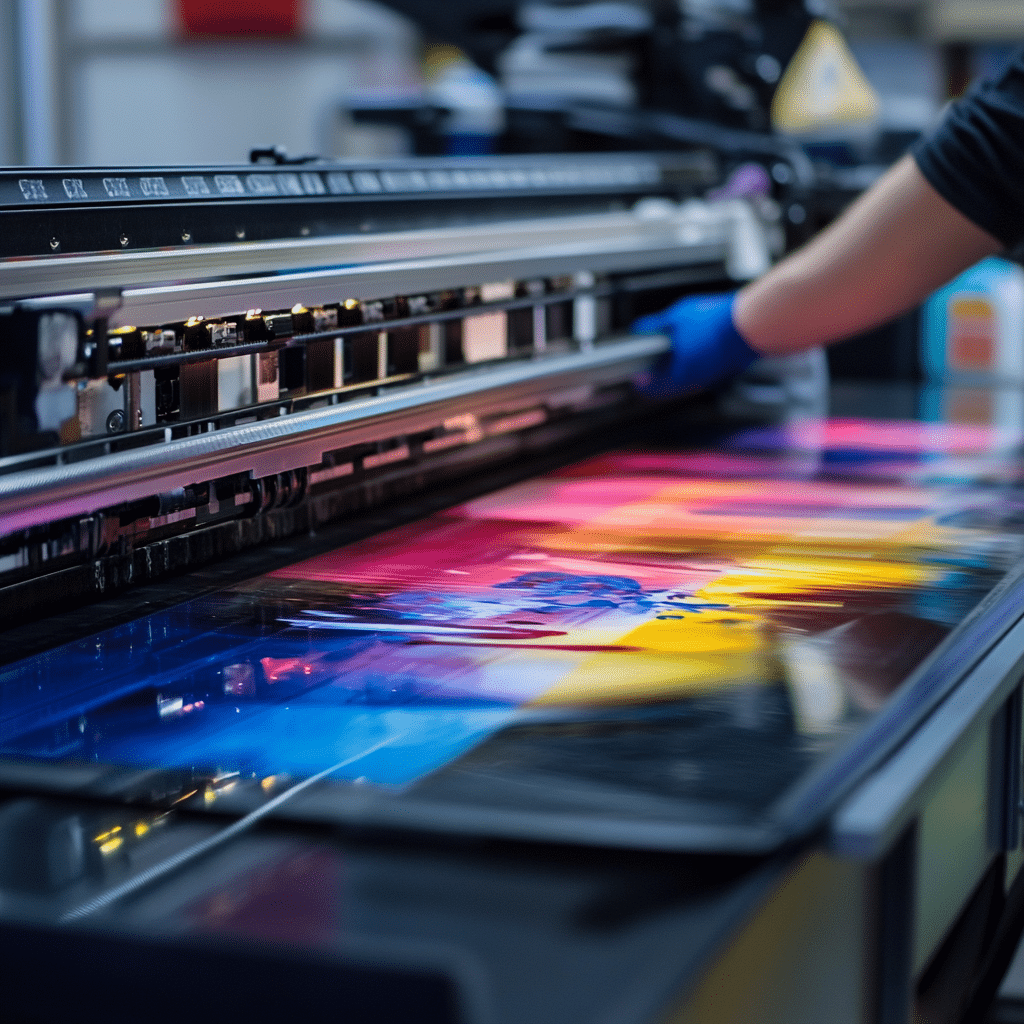

This is where the rubber meets the road with ink technologies. There are three unique technologies used by sign companies, with most having all three capabilities. The three we’ll discuss are UV (ultra-violet) ink, eco-solvent ink, and aqueous ink technologies.

UV Ink Technology

Let’s dive into UV ink technology first. Printing equipment using UV ink is primarily designed for direct print to substrates like coroplast, aluminum, DiBond, acrylic, and even certain roll products.

What makes this technology unique is its curing capability. What many don’t realize is that this ink does not dry, it’s cured, using high intensity UV lamps that molecularly change the ink from a liquid to a solid.

You can think of it on a microscopic level: the ink droplet is exposed to the UV light and the structure creates a spiked molecule in which the molecules bond to each other and to the material it’s cured on. Curing is an instantaneous reaction. The print is safe and solid to the touch once exposed to the UV lamps.

Eco-Solvent Ink Technology

The second ink technology is eco-solvent. It’s complex and used primarily on products like wrap vinyl, decals, banners, and other types of roll materials.

The principle behind this technology is based on the solid color pigments suspended in a solvent to make it possible to flow micro-picoliter inkjet droplets.

Eco-solvent printers use three separate heaters: first, a pre-heat that warms the media in order to open the pores of the material being printed on; the second heater is the platen heater, which is warmer than the pre-heat, and further opens the pores in the material to receive the solid color pigment and embed those solid particles; the third heater is the dryer heater, which is usually considerably hotter than the other two heaters that assist in flashing off the solvent, leaving just the solid pigment on the material.

Aqueous Ink Technology

The third ink is the one most anyone with a home color printer has: those printers use aqueous ink.

Aqueous ink produces a more finite dot, as compared to the previous two ink technologies. Aqueous inks allow you to generate truly photo-realistic prints.

The paper that’s used is the key, as it has a coating to receive the ink and bond, instead of staying liquid. You see commercial usage of aqueous prints in things like movie theater posters, or for high-end event signage on stanchion frames.

Aqueous ink technology excels at photo realistic results. Its only downside? It’s just not optimal for use outdoors. Lamination will keep it dry and partly protected, but humidity or sun exposure will degrade the ink rapidly, starting with magenta.

Recommendations

At Black Creek Signs, we’ve used many varieties of each of these ink technologies over the years.

- Aqueous ink is perfect for high-end large format printing or anything you want to keep and display indoors, or put in a file cabinet.

- If you want a vehicle wrap or decals, go with eco-solvent ink.

- If you can get direct print rigid substrates like coroplast or aluminum, UV ink is the way to go.

If you found this post interesting and wanting more details, please contact us anytime.